Aquafine UV systems are trusted by the biggest brands in the microelectronics market

With over 900 installations in microelectronics fabs globally, Aquafine® Ultraviolet light (UV) systems have a strong global performance record and are trusted by the biggest brands in the industry. We understand the challenges faced in the design and construction of a system for microelectronics production and have the expertise to help with how to integrate with existing systems and ensure optimal performance.

Ultrapure water (UPW) is required at nearly every stage of the microelectronics manufacturing process and is an essential resource to the microelectronics and semiconductor industries. Aquafine UV Systems commonly perform three functions in producing ultrapure water - microbial inactivation via UV Treatment, TOC (total organic carbon) reduction and chlorine and chloramines reduction. The state-of-the-art water treatment systems are engineered to focus the power of concentrated UV light using specially designed Aquafine Colorguard UV lamps which are recognized in the industry for unsurpassed performance and reliability.

UV, in combination with ozone, provides a synergistic approach toward the reduction of trace organics which are among the most difficult contaminants to control in a pure water system. As critical dimensions for integrated circuits continue to decrease and transistor capacities continue to increase, contaminants in the parts per trillion ranges can produce yield-impacting defects. Organics are polar and weakly ionize in ultrapure water. This poses a considerable challenge to ion exchange resins. To prevent TOC leakage from polishing deionizers, silica and/or boron levels are typically monitored to determine when regenerations should be performed.

A microelectronics water system could have several locations where UV equipment would be installed. Some typical locations would be post-carbon filter and pre-RO (reverse osmosis). When installed downstream of the carbon bed and/or directly upstream of the RO unit, a UV system can significantly reduce the microbial counts by inactivating the microbes present in the influent stream. Inactivation is also recommended for the process distribution loop and pre-storage tank.

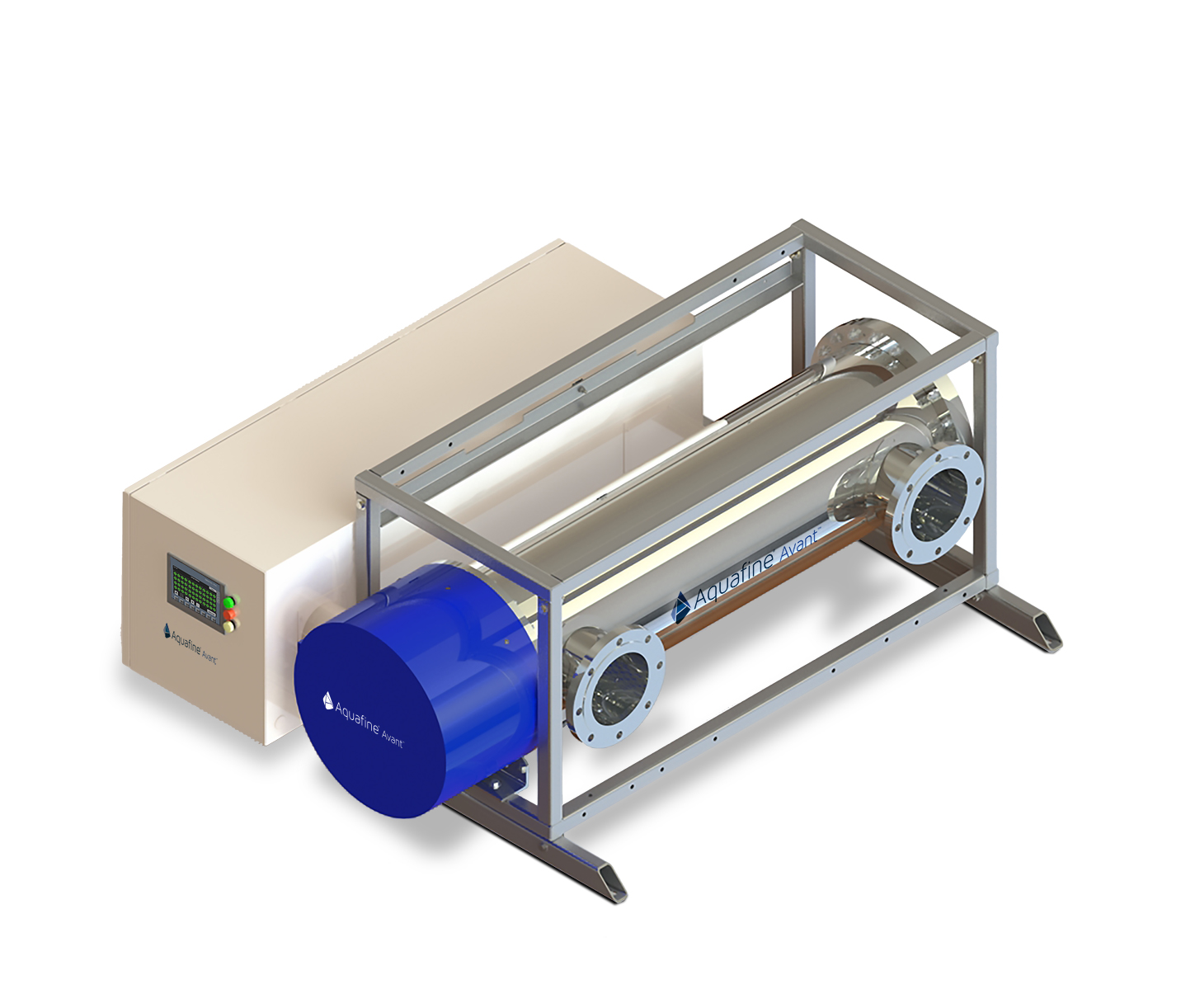

Avant utilizes less energy and provides full flexibility for skid-mounted designs, with the ability to mount up to eight reactors. Avant’s innovation, and best in-class components reduce the total cost of ownership and drastically simplify operation and maintenance. Avant is the ideal solution for ultrapure water (UPW) plants in need of revolutionary UV technology.

The OptiVenn Series is a family of robust and flexible UV Systems with advanced technology designed to meet the stringent requirements of the Microelectronics and other Industrial Markets. The chamber and control panel are extremely compact, and offer flexibility of installation to accommodate into different skid designs or as a stand-alone UV system.

Have questions? Call us at 1 (888) 220-6118 or complete the form below.